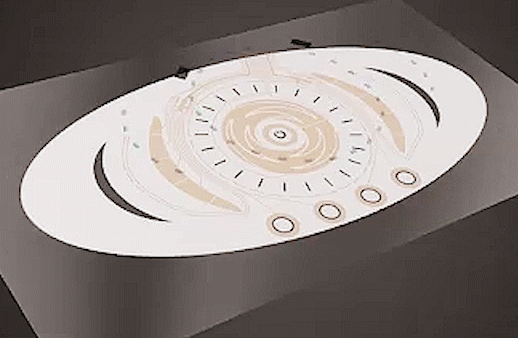

How to Put an Electric Control Button INTO the Surface…

TactoTek a structural electronics manufacturer is using plastics to make vehicle ‘connectivity’ more human. The “touchy-feely” printed circuitry of in-mold electronics uses injection molded plastic in several layers, to create a custom “in-situ” part that replaces many standard multi-part switches, knobs, controls and wiring.

Learn More

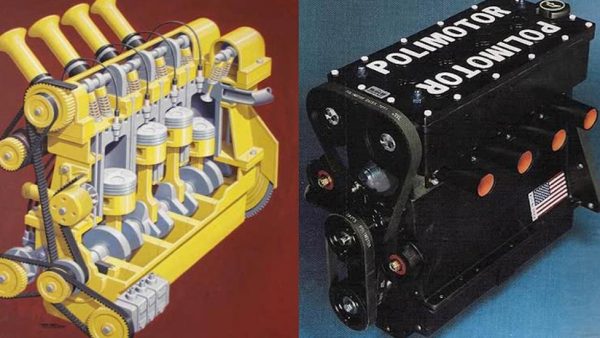

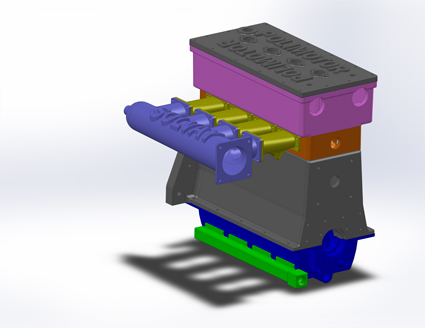

You Won’t Believe This: A REAL Plastic Engine

Solvay a chemistry company known for modern innovation for 153 years is a key sponsor for the Polimotor 2 project: an initiative to build an “all-plastic” engine that reduces overall engine weight by up to 30%. How is it possible to take 30% of the weight of an engine block off? The engine cylinder sleeves are metal; but the block is a tough, resilient thermoset plastic.

Learn More

Autonomous Car Design Beats Detroit Traffic and Parking Lot Congestion

When designing a vehicle for Detroit in 2035, Zachary Rusack, (College for Creative Studies) had one lingering question. Should we change the city or change the vehicle to improve transportation?

Learn More

Lightweighting in the 2017 Green Car of the Year

Electric cars can play an important role making our world more sustainable and energy efficient, and helping the automotive industry meet growing global emission regulations. However, some consumers still view EVs with practical skepticism for their day-to-day lives, due to the often limited driving ranges offered …until now. Enter the Chevy Bolt, 2017’s Green Car […]

Learn More

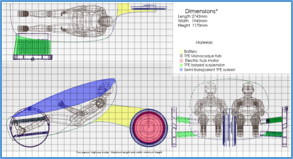

From the Detroit Auto Show: It’s a Car, It’s a Boat, It’s… the Future

When Lucy Lee, a student at the College for Creative Studies (CSS) in Detroit, Michigan, was tasked with designing an environmentally sustainable vehicle of the future, she produced something that utilized the city’s most abundant resource ー water. The CCS students were presenting at the Plastics News Automotive conference held in conjunction with and during the North American […]

Learn More

Plasma Automotive Bonding Lasts a Lifetime

Have you ever wondered how the paint sticks to your car so well? Or, what helps it’s 30,000 parts stay connected over the course of its average 11-year life? The automotive industry relies on innovative manufacturing practices to help ensure each vehicle and its surfaces are finely tuned to run, look, and feel the way […]

Learn More

Incorporating Plastics Into Heavy Duty Trucks to Meet New Fuel Efficiency Standards

The United States has taken a strong stance on reducing greenhouse gas emissions and increasing the quality of our climate through the tightening of vehicle fuel economy standards. On August 16th, new standards were established for medium and heavy-duty trucks to help reduce GHG emissions and energy consumption while increasing fuel efficiency. These standards, finalized by the U.S. […]

Learn More

Reversible Bonding in Multi-Material Vehicles: How It’s Done Part II

In our last post, we introduced the concept of reversible bonding, and explained how thermoplastic adhesives could only be effective in today’s cars if there were a lightning-quick method to heat up the adhesive, form a strong bond, and cool the joint and material in under a minute. Today, this has become a reality thanks to researchers […]

Learn More

The Case for Reversible Bonding in Today’s Automotive Assembly Part I

We’ve been using plastics and fiber reinforced plastic composite materials to make cars for several decades now, and with good reason. Compared to metals, they are lightweight and offer high design flexibility. Plastics can be formed into just about any automotive shape you need – for style, aerodynamics, or both. But more than just for looks and style, today’s […]

Learn More

In-Mold Electronic Inks: A Union of Form and Function for Printed Plastic Car Parts

A new development may change the way we print and manufacture electronic automotive plastics forever – making cars lighter while improving their appearance and functionality in the process. According to DuPont, their “unique suite of In-Mold Electronic Inks are enabling touch controls to be directly embedded inside of plastic parts by printing circuits directly onto plastic sheets, which are then […]

Learn More

Plastics in Automotive: American Chemistry Panel at SxSW Eco

SXSW Eco is an annual conference that attracts thought leaders from around the world to explore and co-create solutions for a sustainable world. Each year the event attracts thousands of professionals to examine critical challenges of our times through a lens of design innovation, policy tipping points, technological breakthroughs, conservation practice, entrepreneurial spirit, and creativity to […]

Learn More

Breakthrough Innovation! Meet the “Polimotor 2”

Moving Towards an All-Plastic Car Engine Auto designers and manufacturers have been swapping traditional materials for plastic car parts for some time now, and the reasons for doing so are clear: plastic car parts are lightweight yet strong, and can help automakers boost MPGs as they strive to meet increasingly strict CAFE standards. However some car parts have been easier to replace […]

Learn More

Plastic Auto Parts: BMW i3 Tour of Carbon Fiber Reinforced Plastics Body in White and Crumple Zone Physics

The automotive industry continues to embrace sustainability and plastic and polymer composite lightweighting to increase fuel efficiency. Several new and exciting safety and performance developments have arisen—many from BMW. In this exclusive video, Franz Storkenmaier, BMW Group’s Head of Lightweight Construction & Vehicle Weight division highlights automotive lightweighting and the dynamic front-end vectoring technology of […]

Learn More

Dual Tracks to Automotive Lightweighting

In this video, John McElroy (the host of Autoline Daily) offers his views on the future of plastics in the automotive industry. The industry as a whole, he says, will likely follow two different tracks, with individual automakers opting for different approaches. The first track, represented by cars like the BMW i3, is an all-in approach – virtually the […]

Learn More

How Automotive Lightweighting Is Done: The Coming Revolution

How do you lightweight the automotive industry for fuel efficiency and safety – so fast? Tomorrow’s cars need to be safe and fuel efficient, so automakers must pursue materials that are incredibly strong, but weigh less. There are currently a variety of materials used in automotive parts for these purposes, so we predict the future […]

Learn More

Moving Safety from the Racetrack to the Highway: Keeping Cars Safe with Automotive Plastics

Safety is important for anyone operating a vehicle, but at 200+ mph, it’s especially crucial for racecar drivers. Thus it makes perfect sense that automotive designers are borrowing materials and safety ideas to build safer cars of the future. Specifically, automakers are looking at the ways that carbon reinforced plastic composites (CFRP) have helped keep racecar […]

Learn More

Detroit Auto Show Recap: Automobile Lightweighting on Autoline.tv

At the 2014 Detroit Auto Show, John McElroy, host of Autoline.tv, moderated several panels as part of the Autoline Supplier Symposium event. ACC’s Automotive Team Chairman Matthew Marks joined the final panel of the day to discuss automotive lightweighting alongside Jay Baron (President & CEO, Center for Automotive Research) and Randall Scheps (Aluminum Associations Group (ATG) and Marketing […]

Learn More

The Revolution: How Injection Molded Carbon Fiber Reinforced Plastics Will Be an Auto Industry Game Changer

Both fast cycle times and predictable strength are required to make a material viable as an automotive part. When it comes to plastic car parts, the plastics industry demonstrate great weight savings (for fuel efficiency) but production time needs to be closer to the speed of a metal stamping machine if plastics are to replace its heavier […]

Learn More

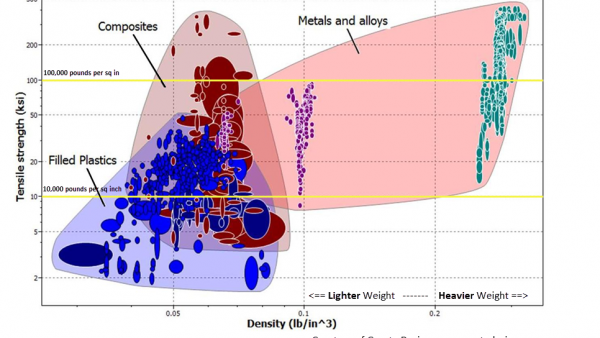

Lightweighting in Cars: One Weird Chart That Should Convince Auto Makers

You’ve seen those online ads: “One Weird Trick That Always Works!” Well, we found one weird chart that really does deserve attention. With strict government CAFE standards requiring higher efficiency vehicles by 2025, choosing the right materials for automotive car parts is more important than ever.

Learn More

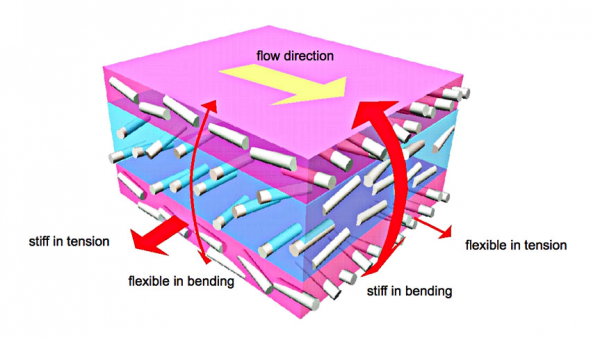

Fiber Modeling for Long Glass Molding Developed by National Labs – Industry First

Material innovation and lightweight fiber composites are transforming the global automotive industry. Short glass fibers (0.2 – 0.4mm) gave new strength to plastic automotive parts as early as the 1950’s. Today’s “laid up” (not injected or extruded) plastic carbon fiber sheet configurations are lightweighting racing and high performance vehicles: the Chevy Mi-ray Concept, the BMW i3, […]

Learn More