A car’s electrical system used to be limited to a few components. Not anymore. In the last 20 years, a car’s electrical anatomy has undergone major changes. Electrical components now automate systems from ABS to satellite radios. Plastics make that possible.

Switches and Sockets

These components need to be strong, light, and low-friction. Plastic is a perfect material for the job. Low friction plastics, like Acetyl, can be used in steering column switches. Using plastic means these switches require less maintenance than metal.

These components need to be strong, light, and low-friction. Plastic is a perfect material for the job. Low friction plastics, like Acetyl, can be used in steering column switches. Using plastic means these switches require less maintenance than metal.

Then there are the places where metal can’t take the heat. Nylon works well under the hood, and can stand up to hot motor oil when built into the gearbox. Sockets made from high performance plastics can withstand high temperatures and resist corrosion.

Connectors

Polybutylene terephthalate (PBT) is a thermoplastic polyester. It’s the ideal connector for fuel injectors. European manufacturers have even started to use a recycled version to build connectors. Recent innovations in moisture resistance have also allowed for increased use of Nylon in connectors.

Polybutylene terephthalate (PBT) is a thermoplastic polyester. It’s the ideal connector for fuel injectors. European manufacturers have even started to use a recycled version to build connectors. Recent innovations in moisture resistance have also allowed for increased use of Nylon in connectors.

The Volt Battery is a series of interconnected plastic parts. It gangs electrical connections together creating the electric propulsion unit.

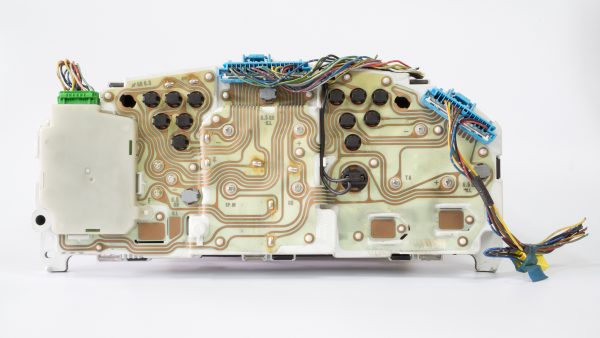

Circuit Boards and Wiring Harnesses

Fifteen years ago, dashboards were crammed with heavy copper wiring. But advances in acrylic fiber optic cables have eliminated the need for copper. This means enhanced illumination of the interior, more accurate GPS data, and highly responsive ABS sensors. Using fiber optics reduces the overall weight of the vehicle as well.

Stay Up to Date

Sign up to receive our newsletter and get the latest delivered to your inbox.

The Insider's View

Follow our blog for a unique look at how plastics are changing the way we make cars.

Learn More