Safety advances in today’s materials save countless lives. Air bags, windshields, sunroofs plus energy absorbing innovations reduce vehicle fatalities. Plastic front-end modules, modular seats and energy-absorbing bumpers help save lives every year.

Airbags

Airbags are one of the most important safety innovations of recent decades (IIHS). They save lives.

Airbags reduce driver fatalities in frontal crashes by 29 percent. An SUV driver with side airbags can reduce risk of death by 52 percent. (IIHS)

A new seat belt contains an inflatable airbag sewn inside! Special plastic webbing in the shoulder belt hides an inflatable airbag. The airbag bursts across the chest area staying inflated protecting occupants.

Impact

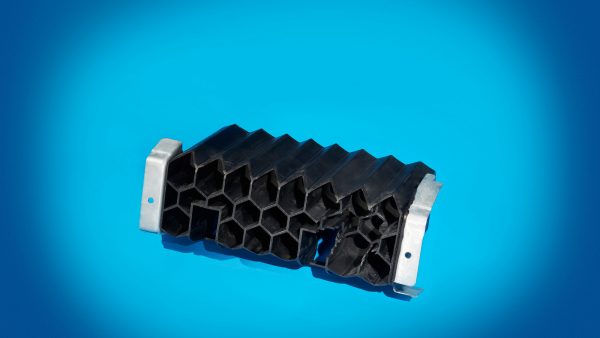

Plastic composite structures can help lightweight vehicles while preserving safety features. When a vehicle crashes, engineers want the structure to crush in a predictable way. Automotive materials should absorb, not transfer, the “impact energy” to humans. The industry calls this a “controlled crush.”

Fiber-reinforced polymer composites absorb four times the crush energy of steel. The B-pillar is the support post that connects a vehicle’s roof to its body. It is at the rear of the front door and provides the major source of resistance to intrusion during a collision.

The National Highway Traffic Safety Administration recently funded a study on B-pillars. The study looked specifically at a composite intensive carbon fiber thermoplastic B-pillar design. The goal was to determine the design’s weight savings and vehicle crash safety as compared to a metallic baseline. The B-pillar showed 60 percent weight savings, and satisfied side-impact crash requirements. Computational tools modeled the dynamic impact and crush response B-pillars.

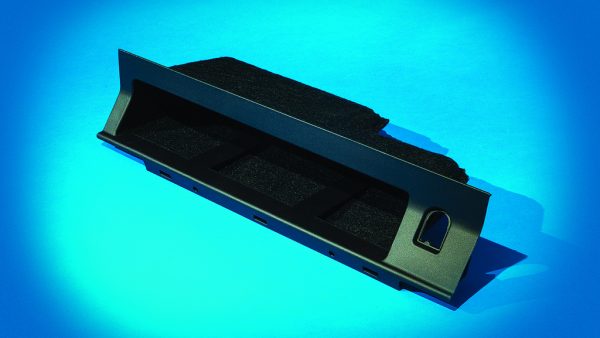

The Society of Plastics Engineers cites the 2018 Ford Expedition for a collapsible glove box. The new, energy-absorbing design collapses during impact to help prevent severe femur (legs and shin) loads. Also, it is adaptable to other vehicle lines and assisted in achieving a 5-star crash rating. (Another example is this addition to front seat safety.)

Plastics are helping save lives during pedestrian impacts too. Polycarbonate-blend bumpers help protect passengers in collisions. Plastics also enable faster deployment for greater pedestrian protection in Ford vehicles. A flexible pedestrian-protection crash direct-mounted sensor bracket injection molded in plastic. See more in our “Crumple Zone Blog” and our tour of the BMW i3 Carbon Fiber Chassis Safety Components.

Download Crumple Zone Resource

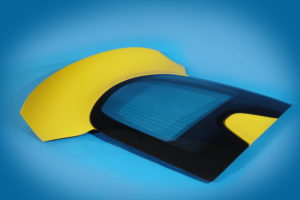

Windshields, Windows & Sunroofs

North American windshields come as a multi-layer unit. Picture a thin layer of plastic between two thinner sheets of glass. The combination can be thinner, lighter and stronger than tempered glass alone. The tear-resistant plastic layer helps prevent occupant ejection. In fact, NHTSA estimates these layers help prevent over 300 fatalities a year.

Lightweight plastic components for roofs lower the center of gravity reducing likelihood of tip-over during deep cornering accident maneuvers. Clear non-distorting polycarbonate can now be UV resistant and reduce weight significantly. Entire roof assemblies can be polymer based.

Stay Up to Date

Sign up to receive our newsletter and get the latest delivered to your inbox.

The Insider's View

Follow our blog for a unique look at how plastics are changing the way we make cars.

Read