Self-driving cars are coming soon. Detection systems behind plastic “radio-frequency-transparent” front ends read the road ahead. Lightweighting can offset the weight new technologies add to autonomous vehicles, helping extend battery range. Various automotive plastics will help shape the ways in which drivers and passengers interact with new sensors, telematics, navigation, flexible interiors, infotainment, and interactive displays.

Safety

Fully autonomous vehicles hold the promise of drastically reducing crashes. But during the transition, crashes which will someday be avoidable will continue to happen. Safety is an ongoing critical, fundamental priority. Enabling seat belts, airbags, side-curtain bags, windshield inner-layers, pedestrian collision protection safety features and padded dashes, plastics will continue to enhance safety in self-driving cars. Additional brake boosters can be programmed to stop the vehicle. An airbag control unit could do double duty as a backup to guide the vehicle. Telematics, the coordination between cellular and GPS signals, will use weather resistant composite materials for connection harnesses, housings, and wiring. “Thin-walled” composites and honeycombed materials free up safety-system cabin space. Lightweight multi-material composites can replace heavy structural metals, freeing up the weight needed to enable this coming electronic revolution.

Sensors

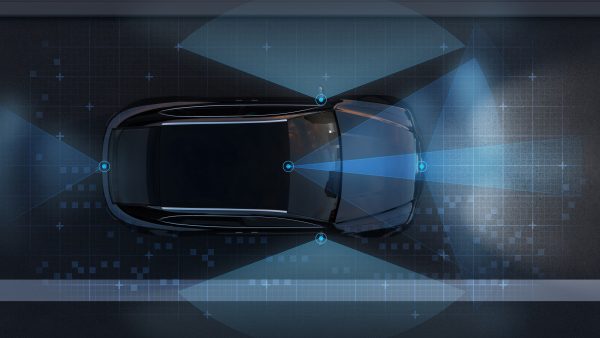

Chemical & Engineering News reports “Carmakers will need plastics for all the new cameras, radar, LIDAR, sensors [and redundant safety] on the vehicles.” The use and the dependability of plastic electric sensors, wiring, harnesses, and connectors will be essential for autonomous vehicle deployment and life-saving safety features. Interior vehicle safety sensor communication and vehicle-to-vehicle communication will require redundant safety features to remain continuously reliable.

Today’s cars have hundreds of plastic connectors in service per vehicle. They help sustain today’s typical 10-12 year vehicle lifespan. More than just reliable, plastics spur innovative new technologies. Sensors in autonomous vehicles must “see” through body panel material to perceive the vehicle’s surroundings. Radio frequency transmissions that allow vehicle-to-vehicle sensors can penetrate plastic shields, bumpers, films, panels, and fascia. At the same time, sensors, switches, relays, and timers, consolidate into plastic assemblies, satisfying space requirements, weight reductions, and security demands. Light-transmitting plastic fiber optics can enable “speed-of-light” communications among life-saving sensors and monitors throughout the vehicle to reduce the time between incident and safety device deployment.

LIDAR

An autonomous car will use sensors that “peer” through plastics like Light Imaging Detection and Radar (LIDAR) to successfully navigate paved roadways and off-road trails. LIDAR uses lasers to create a 3D map of the world in real time, on the fly, detecting obstacles and identifying the shapes and boundaries within and along a roadway. Thermoplastics, like polycarbonate, permit light and imaging transparency. Integrating thermoplastics and plastic films into front grills and bumpers can allow engineers to mount LIDAR detection sensors “invisibly” into the design of a vehicle’s grill, side panels or bumpers.

Engineers calibrate plastics materials to allow certain radio frequency signal wavelengths to pass through them, undisturbed. Plastics can achieve permeability or, signal transparency, as on today’s cell tower beaming covers. This quality will allow future V2V (Vehicle-to-Vehicle) communication in a car and through the transportation infrastructure.

Durable plastic network vehicle charging stations, traffic flow monitors, stop light timers, lane diversion signals, temporary barriers, travel direction signs, and police and fire right-of-way equipment will allow infrastructure communication to vehicles emitting similar signals to maintain safety and flow. Plastics will not only be essential to self-driving vehicles but also essential to the transformative infrastructure.

Flexible Seating and Interior

Lightweight plastic interior options can be multi-configurable. Dual forward-facing seat backs might reverse or fold for storage. Today your vehicle serves as a commuter SUV. Tomorrow its role might be a commuter/travel entertainment center. Do you need a foldaway desk? Want to see a movie or play a video game on your moonroof? Plastics can enable these and more, including providing antimicrobial and self-cleaning and healing properties as well as durability, tactility and natural appeal in new automotive interior materials.

Ride Sharing

Plastics will enhance occupant safety and increase weight efficiencies of in-service ride-sharing vehicles to allow ride sharing to reduce travel times, lessen congestion, and increase handicapped accessibility. Shared autonomous vehicles will need additional complex computational and communications power onboard to navigate. Plastics can conserve weight, consolidate parts and make space for these required electronics. Carbon fiber and polymer composites will play an additional role in enhancing safety and security in autonomous ride sharing. Carbon fiber composites can provide improved structural rigidity. For instance, roofs can gain vehicle torsional rigidity while reducing overall weight. Carbon fiber roof structures can lower the center of gravity making cornering and quick avoidance maneuvers easier to accomplish. Carbon fiber has a high strength-to-weight ratio. It can be as strong as metals but at a fraction of metals’ weight. Plus, plastics can expand electric vehicle battery ranges and improve engine performance. Reducing vehicle weight can mean more travel-time and less downtime recharging. Additionally, corrosion resistance afforded by a plastic body and chassis parts will help keep “constant-use” vehicles in operation with less corrosion and rust.

Stay Up to Date

Sign up to receive our newsletter and get the latest delivered to your inbox.

The Future Starts Here

The Automotive Plastics and Polymer Composites Roadmap for Future Mobility is charting the path forward in autonomy, connectivity, circularity, electrification, shared autonomous vehicles, and sustainability.

Access the Roadmap