Advanced driver-assist safety (ADAS) technologies and other technological breakthroughs are helping to gradually relieve human drivers from controlling passenger vehicles. Because they will be able to process more information and react faster than humans, it has been estimated that autonomous vehicles will help to reduce the 94% of serious automotive crashes caused by human error.19

Once the most significant barriers to adoption—including consumer acceptance, regulations, and economics of alternative car ownership models—have been overcome, fully autonomous vehicles will offer significant advantages and value, including:

- Allowing passengers to safely participate in non-driving activities like resting or working while traveling

- Reducing road congestion and traffic delays

- Improving fuel efficiency

The trend toward embracing autonomous driving presents a broad range of opportunities for advanced plastics and polymer composites in the following areas:

Flexible Interiors

Design Impacts

Interiors are likely to feature numerous sensors and biometrics for vehicular access, safely monitoring driver behavior, and personalized riding experiences without sacrificing style or aesthetics.

Higher levels of autonomy could improve the comfort and modularity of vehicle interiors including more flexible seating configurations.

Opportunities for Advanced Plastics and Polymer Composites

Engineered automotive plastics can enable surface- and fabric-embedded flexible sensors without interfering with radio signals.

Protective plastic screens, coatings, and projection surfaces can provide scratch-, chemical-, and shatter-resistance for entertainment and information display screens.

Fleet and rideshare vehicles will require anti-microbial plastic surfaces to accommodate multiple passenger trips.

Collaborative Activities

Integrated Sensors/Biometrics

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Define materials requirements in terms of transparency and opacity for state-of-the-art biometric sensors | Near |

| Design additively manufactured thermoplastic composite tooling configuration for fabricating interior components | Near |

| Conduct benchmark study of sensor technologies used in advanced safety systems for driver monitoring | Near, Mid |

| Establish materials-agnostic automotive industry standards for interior sensor systems | Mid |

| Establish industry-wide indirect measurement methods for monitoring driver health and behavior; include mapping and scoping parameters for safety, comfort level, driving experience, etc. | Mid |

| Design engineered automotive plastics for flexible sensors that are integrated into interior fabrics and surfaces | Mid, Long |

Reconfigurable Seating

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Standardize test methods to assess the performance of materials with high daily usage rates | Near, Mid |

| Develop next-generation automotive seating with innovative composite materials and engineered plastics | Near, Mid, Full |

| Develop next-generation automotive seating with innovative composite materials and engineered plastics | Mid |

| Investigate passenger comfort requirements using human finite element (FE) models | Mid |

| Demonstrate modularity of lightweight seats to create new spaces and configurations | Mid |

| Increase collaboration efforts between NHTSA and the automotive industry to upgrade existing safety standards to account for flexible seating configurations | Mid, Long |

| Upgrade existing safety standards and crashworthiness test methods and countermeasures for reconfigurable seating | Mid, Long |

Safety

Design Impacts

While autonomous driving technologies are expected to reduce human-caused crashes over time, automakers still require advanced materials to improve the crashworthiness of windows, airbags, and other energy-absorbing components. Regulations tailored for incumbent legacy materials could potentially inhibit the integration of new or novel materials for automotive applications.

Future vehicle designs may substitute lighter weight alternatives for systems such as glazing closures, body structures, and interior components.

Automotive exteriors must be externally detectable for a broad range of sensor wavelengths and fully functional in difficult weather conditions while meeting consumer demand for styling and brand differentiation

Opportunities for Advanced Plastics and Polymer Composites

A recent vehicle mass reduction study demonstrated that B-pillar structural components made with thermoplastic-based carbon fiber composites can satisfy side-impact crash requirements and deliver a 60% weight reduction compared with the steel baseline.20 Composite front-end structures can provide the same crash protection in less space than a steel one.21

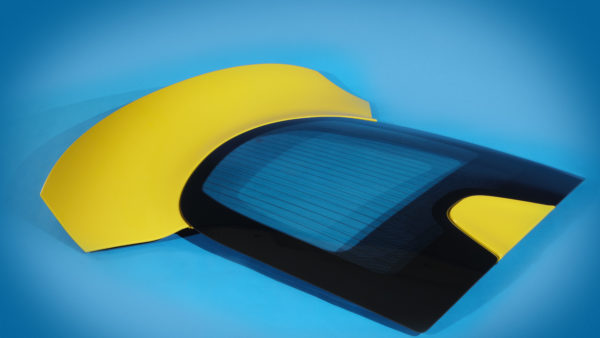

Low-density polymeric glazing materials could help reduce vehicle weight while providing increased acoustic damping performance for improved passenger comfort. Hard-coated polycarbonate is a beneficial alternative to traditional automotive glazing due to its high transparency and clarity, low weight, huge freedom of design, and strong impact resistance.22

Sensor-embedded exterior surfaces will use signal-transparent plastics to enable two-way connectivity with other vehicles and infrastructure (i.e., vehicle to vehicle [V2V], vehicle to infrastructure [V2I]).

Visually transparent, UV-resistant, and shatter-resistant windows, roofs, and frames could remove blind spots and reduce pedestrian collisions for driver-controlled operations.

Thermoplastic polyolefins and other advanced plastics can be molded into complex shapes to make vehicles quieter and more ergonomic.23

Collaborative Activities

Detectable Exteriors

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| *Demonstrate and prove the effectiveness of plastic and polymer composite components for increasing the ability of autonomous vehicles to detect surroundings during poor weather conditions | Near, Mid |

| Coordinate with original equipment manufacturers (OEMs) to define application specifications and requirements for highly durable, weather-resistant exterior body panels including consideration for embedded sensors and displays | Near |

| Define material property requirements to enable multi-modal sensing (e.g., LIDAR, radar, camera) | Near |

| Investigate enhanced plastic or polymer composite materials and coating for exterior surfaces with high reflectivity and signal transparency | Near |

| Develop sensor-detectable colors to expand options for styling and differentiation | Mid |

| Examine potential solutions to increase visibility of autonomous vehicle exteriors to visually warn pedestrians (i.e., similar to EV warning sounds to alert nearby pedestrians) | Mid |

| Establish industry-wide test methods and standards for automotive exterior surfaces for reflectivity, visibility, and connectivity (e.g., coatings, pigments) | Mid |

| Explore a composite exterior molding process that avoids the need for secondary painting | Mid |

| Develop highly visible reflective pigments with infrared (IR) capabilities (e.g., use IR signals to make vehicle “glow”) | Long |

Windshield & Glazing Closures

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Investigate polymeric materials with dimmable curvatures to customize interior lighting | Near |

| Identify structural requirements for large-span windows and panoramic roof structures with limited pillar support | Near |

| Develop predictive numerical material models for windshield and glazing materials | Near, Mid |

| Conduct integrated analysis of windshield safety and performance | Near, Mid |

| Demonstrate high modulus adhesives of large window components for reduced noise, vibration, and harshness (NVH) and improve passenger comfort | Near, Mid |

| Develop photoactive engineered polymers (i.e., semi-transparent or variable-transparency) required for passenger safety | Mid |

| Develop application requirements of functional window-display materials (e.g., heads-up passenger display, pedestrian warning systems) for Level 4 autonomous vehicles | Mid |

| Design windshields that enhance nighttime visibility for drivers | Mid, Long |

| Upgrade industry standards to accommodate photoactive materials to improve driver vision and safety (Level 1-4 autonomy) | Mid, Long |

| Increase lifespan of transparent windshield glazing materials via improved impact- and weather-resistance (Level 0-4 autonomy) | Mid, Long |

| Integrate electronic display systems to replace select transparent glazing materials (Level 5 autonomy) | Long |

Crashworthiness Requirements

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| *Establish materials-agnostic automotive industry standards to permit the use of innovative materials for lightweight mixed-material assemblies | Mid |

| Engage key industry organizations to achieve consensus on realistic materials-agnostic performance standards | Near |

| Develop predictive numerical material models to improve the energy absorption of structural automotive composites | Near |

| Identify a range of crash scenarios to inform performance and failure prediction models for structural composites | Near |

| Identify required test methods and standards to evaluate structural composite test specimens using dynamic loading rates | Near, Mid |

| Coordinate with appropriate federal agencies to re-evaluate interior crash protection requirements including countermeasures for rear- and side-facing seating configurations | Near, Mid |

| Upgrade existing safety standards and standardize crashworthiness test methods (e.g., rollover, side-impact) to validate structural rigidity of large window components and electrical energy storage systems | Mid |

| Design composites with optimized fiber-matrix interfaces to maximize their energy absorption capabilities | Mid |

| Establish and maintain a database of automotive specifications and materials properties to evaluate the safety and performance of advanced composites | Mid |

| Conduct technical analysis of automotive composites safety and performance to support regulatory standards development activities | Mid |

| Investigate automotive chassis designs to permit interchangeable polymer and composites panels that balance crashworthiness with aesthetic design | Mid |

| Enhance performance and failure prediction models for carbon fiber composite parts | Mid, Long |

Sensors/Light Detection and Ranging (LIDAR)

Design Impacts

Self-driving vehicles will require some combination of embedded sensors such as camera, radar, satellite, and light-based (e.g., LIDAR) detection methods. Standardizing automotive sensor systems will be challenging due to both competitive market forces as well as a limited understanding of which combinations of sensor types will eventually be most in demand.

The sharp increase in total sensors per vehicle will require additional electronics protection to ensure the safe and continued operation of life-saving safety features.

Increased number of on-board sensors and algorithm computing devices will demand improved heat management solutions to ensure safe, continuous operation.

Encapsulant materials must offer physical protection for sensors while permitting full signal transparency for detecting pedestrians, animals, obstructions, and other communications devices.

Opportunities for Advanced Plastics and Polymer Composites

Automakers will require radio frequency-transparent plastics for all cameras, radar, LIDAR, and sensors on vehicles to “see” conditions further ahead.

Advanced polymeric materials permit both light and imaging transparency and can hide multimodal sensor systems behind body panels, bumpers, and grilles.24

Integrating electronic sensor systems will require humidity and temperature resistant plastic materials for connection harnesses, housings, and wiring.

Vehicle systems will require thermally conductive and electrically insulative polymers including adhesives, separators, and housings to maintain safe operation

Collaborative Activities

Electronics Insulators

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Gather reliable information on a broad range of realistic ambient conditions for superabsorbent materials to inform appropriate test methods | Near |

| Conduct a demonstration project for humidity and temperature resistant adhesive technologies for electronics protection | Mid |

| Define materials specifications based on sensor detection and data processing requirements | Mid |

Radio Frequency Transparency

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Define application specifications and requirements for radio-frequency transparency and/or shielding | Near |

| Design automotive composite panels with integrated clips or brackets to accept custom wiring and sensor configurations | Near |

| Design aesthetic embedded sensor systems (e.g., hidden behind plastics such as logos and front-end components with a glossy or shiny appearance) | Near |

| Standardize material characterization methods for sensor-friendly exterior material surfaces including substrates and fillers | Near |

| Design advanced polymer and composite-intensive automotive concepts with optimum integration and concealment of sensor hardware | Mid |

Sensor Standards

| Near (2020–2022)Mid (2023–2025)Long (2026–2030) | |

|---|---|

| Increase education and advocacy efforts to publicize the necessity of advanced plastics for enabling sensor-to-sensor communication | Near |

| Define performance-based specifications and requirements for sensor/LIDAR systems | Near, Mid |

| Standardize communication protocols for interoperability, security, and reliability of multimodal sensor systems (e.g., standardization of input/output signals, data bus, diagnostics software); focus on single consolidated data transmission standard | Long |