It’s estimated that many drivers and passengers spend more than 10 hours each week traveling in automobiles, which are enclosed spaces having numerous touch points. This means increased opportunities for travelers to be exposed to bacteria and viruses. Typical touch points include door handles, seats, steering wheel, gear shift, touch-screen display, and instrument panel.

It’s estimated that many drivers and passengers spend more than 10 hours each week traveling in automobiles, which are enclosed spaces having numerous touch points. This means increased opportunities for travelers to be exposed to bacteria and viruses. Typical touch points include door handles, seats, steering wheel, gear shift, touch-screen display, and instrument panel.

The potential risk may be even more concerning to the 43% of U.S. consumers who use ridesharing at least once per week. Due to the COVID-19 pandemic, hygienic vehicle interiors are becoming increasingly important to vehicle owners as well as ride-share and transit users. A recent survey by market-research firm IHS Markit found that 54% of consumers are interested in having their next personal vehicle equipped with an antimicrobial coating. Noting the need and demand, automakers are accelerating their plans to increase antimicrobial systems in vehicles.

Silver and copper are metals long known for their antimicrobial properties, and the pandemic will likely increase their use in transportation. In 2016, for instance, a new version of Poland’s Solaris Urbino 12 was introduced. The electric-powered bus features handrails made from copper to destroy germs on these important touch points.

Since today’s automobile interiors are mostly plastics and composites, plastics manufactured with antimicrobial and self-cleaning properties may be key to keeping occupants safe and healthy. Important touch-point components could be embedded with nanoparticles of such metals – silver, copper, zinc oxide or titanium oxide. In a recent discussion on how COVID-19 will impact vehicle design, Ford CEO Jim Hackett mentioned the development of nano-level structures, embedded in seat fabrics and other surfaces to rupture and kill bacteria and virus particles. These substances could also be embedded in seat-cover linings removable for cleaning.

Since today’s automobile interiors are mostly plastics and composites, plastics manufactured with antimicrobial and self-cleaning properties may be key to keeping occupants safe and healthy. Important touch-point components could be embedded with nanoparticles of such metals – silver, copper, zinc oxide or titanium oxide. In a recent discussion on how COVID-19 will impact vehicle design, Ford CEO Jim Hackett mentioned the development of nano-level structures, embedded in seat fabrics and other surfaces to rupture and kill bacteria and virus particles. These substances could also be embedded in seat-cover linings removable for cleaning.

Automakers will also work to reduce microbes on exterior car parts and surfaces. Suppliers are developing paints and coatings that are manufactured from natural antimicrobial polymers, while others have silver particles embedded in them.

Since many respiratory diseases are spread through circulating air, designers are also looking closely at vehicles’ climate-control systems. Tesla and Geely Motors are two companies that have announced air-filtration systems that use high-efficiency HEPA filters, whose dense, twisted fibers trap microbe-laden moisture and dust particles.

Photo Credit: Hyundai Motor Group

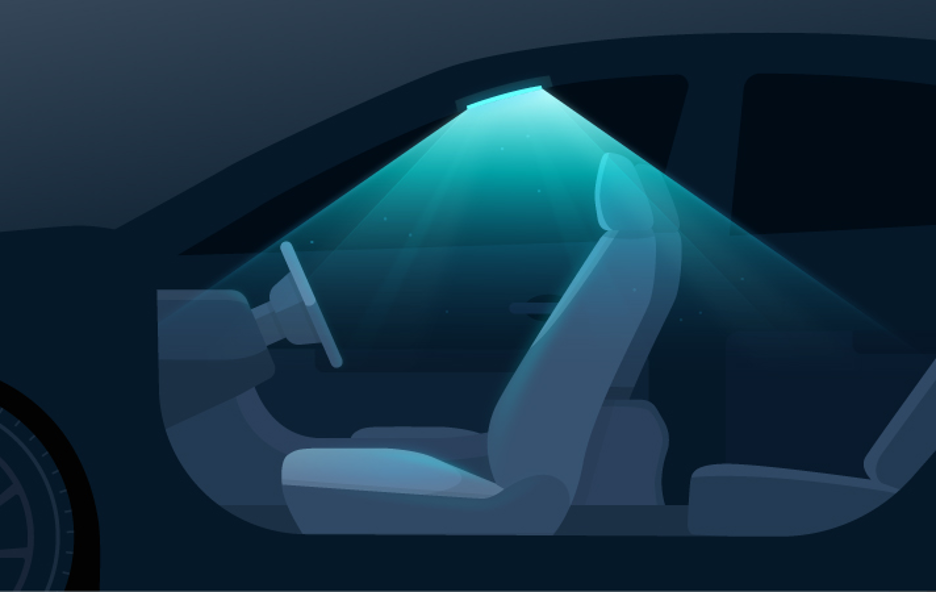

Ultraviolet-C light sterilization — already used in hospitals and some New York City subways — is being considered for cleaning vehicles’ circulating air as well as interior surfaces. Since the UV-C spectrum is dangerous to exposed human skin, UV-C lights could be embedded inside air-filtration systems to clean air while cars are in use. They could also be installed in dome fixtures or headliners to clean steering wheels, seats, and controls when the vehicle is unoccupied. Hyundai Motor Group is one automaker working to install these powerful antimicrobial lights in future car models.

While some germ-fighting technologies – such as removable seat covers – can be added to existing car designs, others may take some time to engineer into consumer-safe components that can withstand years of daily use. Since polymer-based materials have already demonstrated their resiliency, we can expect automotive designers to work hard at incorporating antimicrobial technologies into plastics-related car parts.